1. 3D Printing

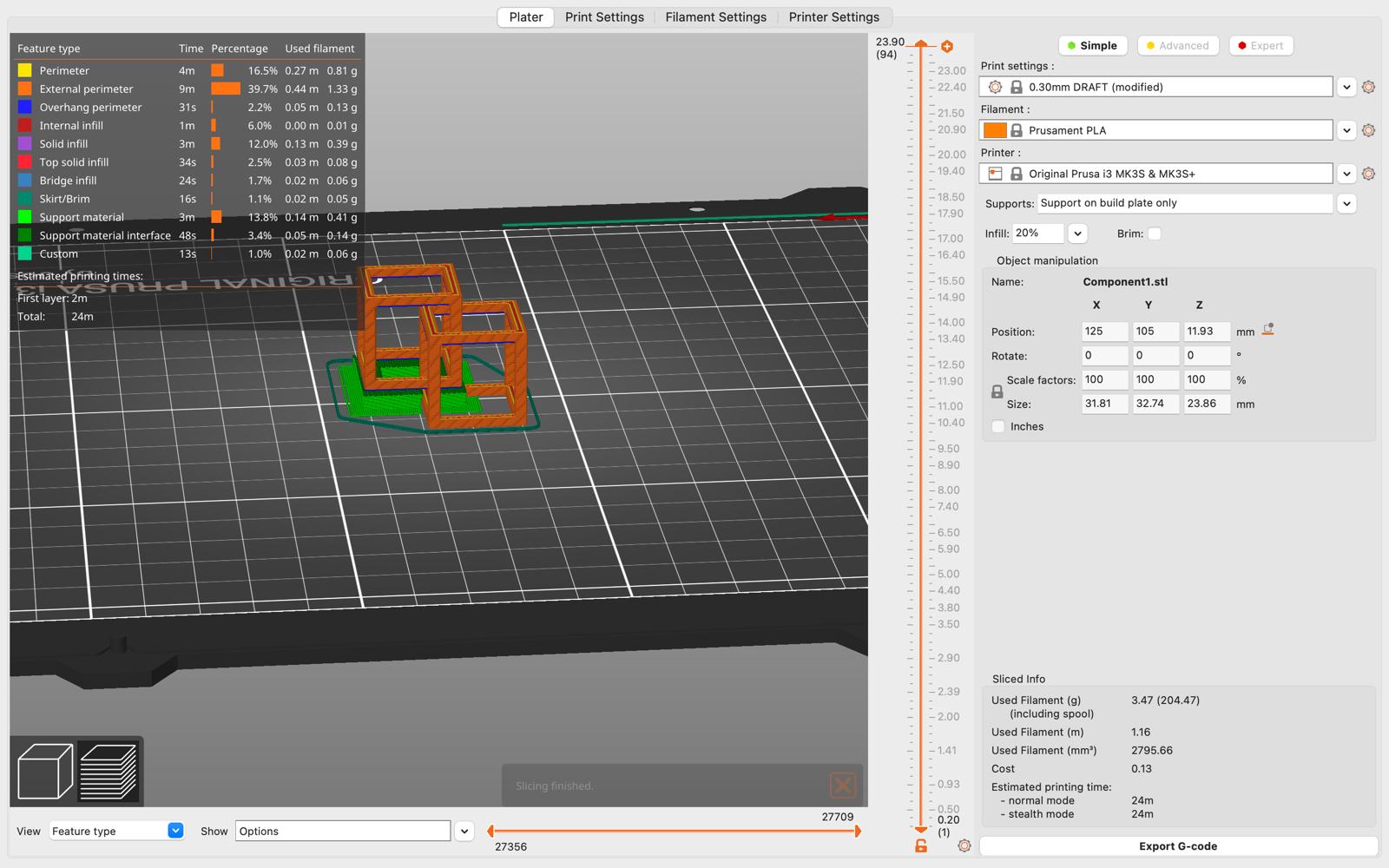

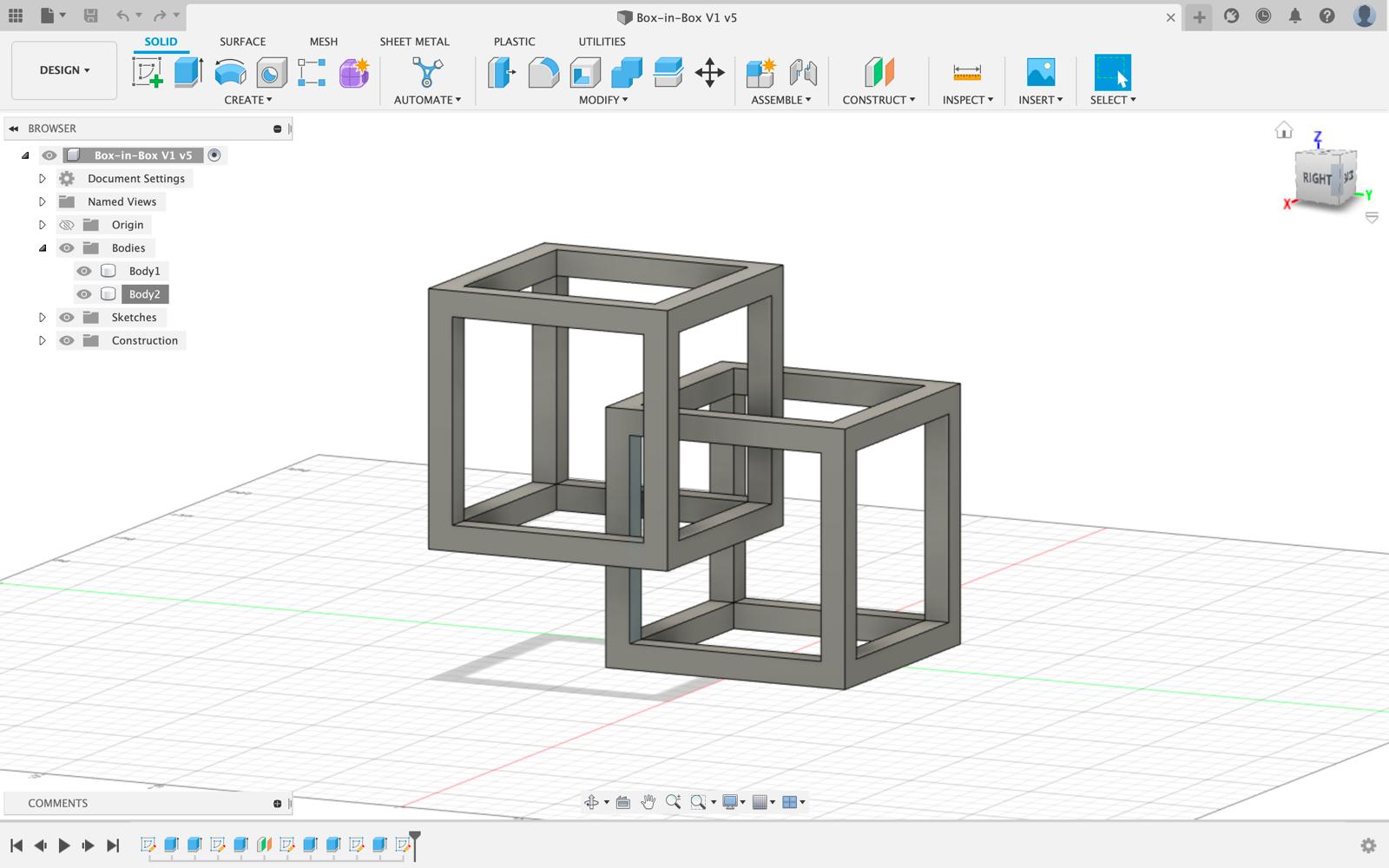

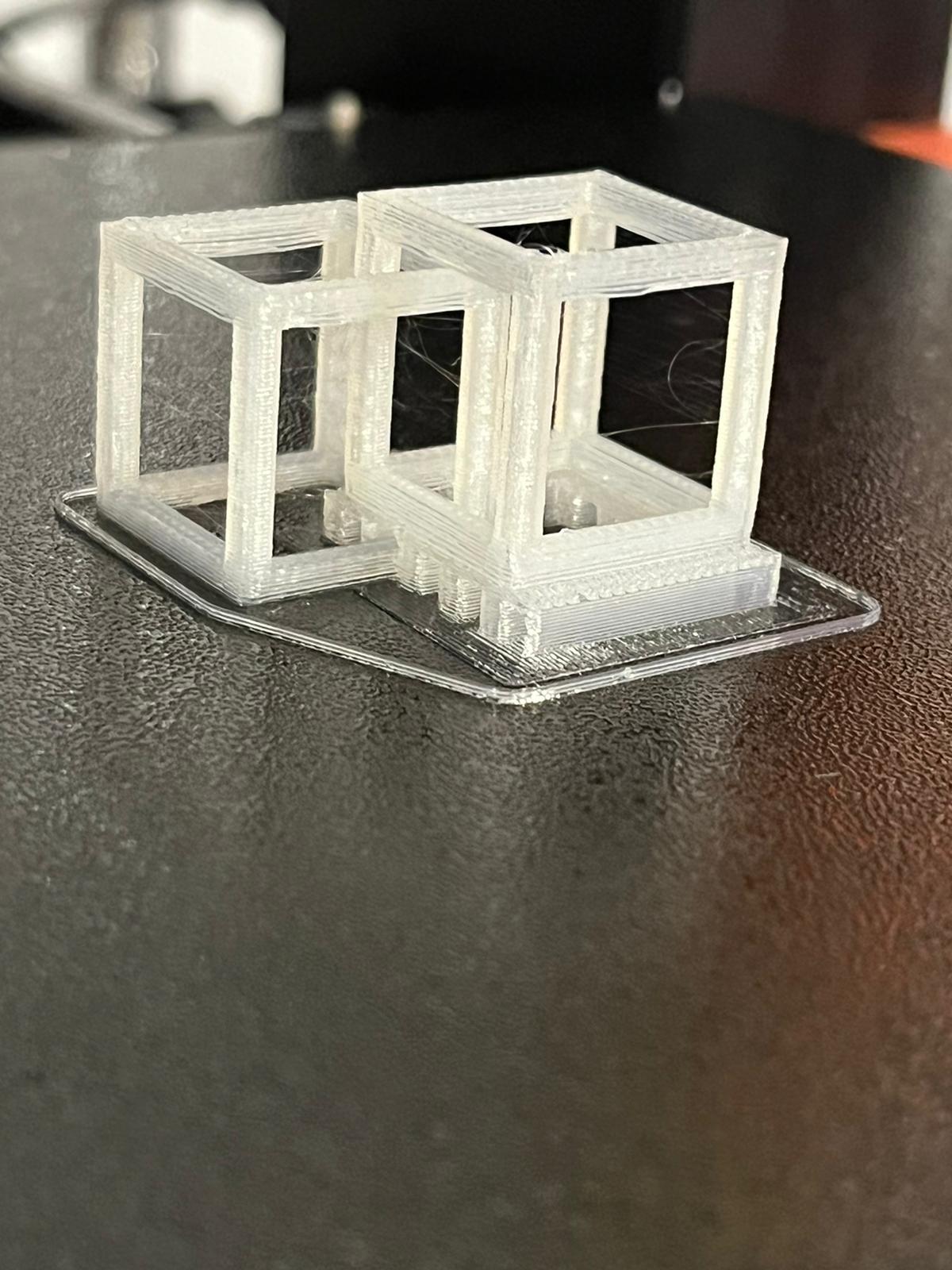

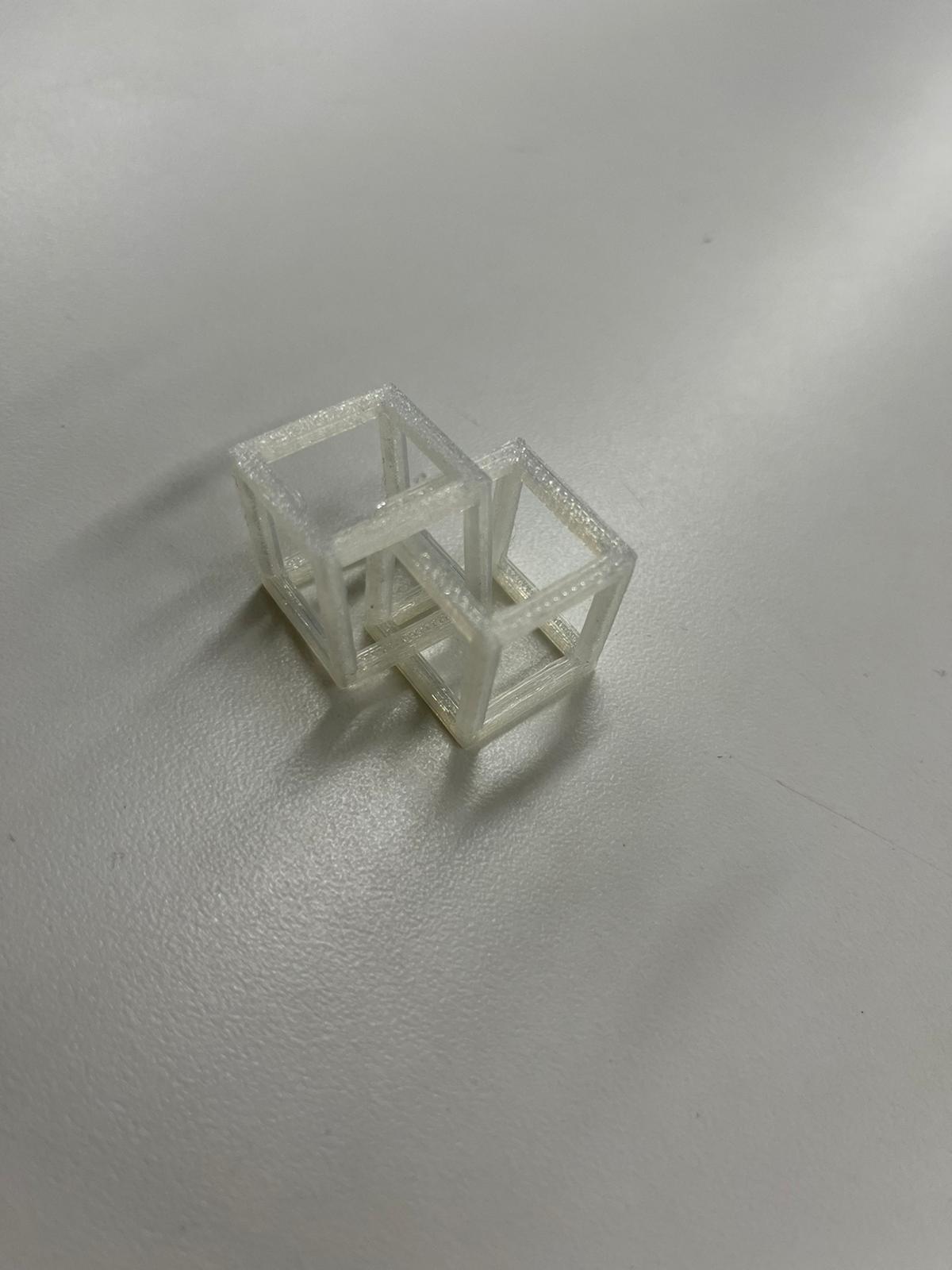

I have never really made something in CAD then 3D printed it, so at the beginning of this week I was starting off pretty mundane by printing a box in a box. This was the first thing that came to my mind when we were talking about additive work. I started off by making one box in fusion using the CAD principles I learned during the laser cutting week. I locked the blue lines and everything. I downloaded PrusaSlicer. Then right clicked on body and hit save a mesh, then set to STL(Binary) then set my Fusion to open up PrussSlicer. The first square I printed I didn't need any support and it printed perfectly. The next step was to add a second square. I added a plane half way up the first square and repeated my process instead of copy and pasting, only because I did not think about that while I was doing it. When I first talked to Leo about reducing the support he suggested that I turn the second box on an and move it as close to the first box as possible. Later Ibrahim gave me another way of thinking about it saying that doing Leo's method would make it really hard to take the supports off. Instead he suggested I use supports that would be easier to take off. In PrusaSlicer we looked at add supports everywhere vs just from the base. I also was introduced ot some of the advanced features such as painting on where I want supports vs where I don't wants supports. We originally hypothesized that the print would fail but in the end it ended up working beautifully.

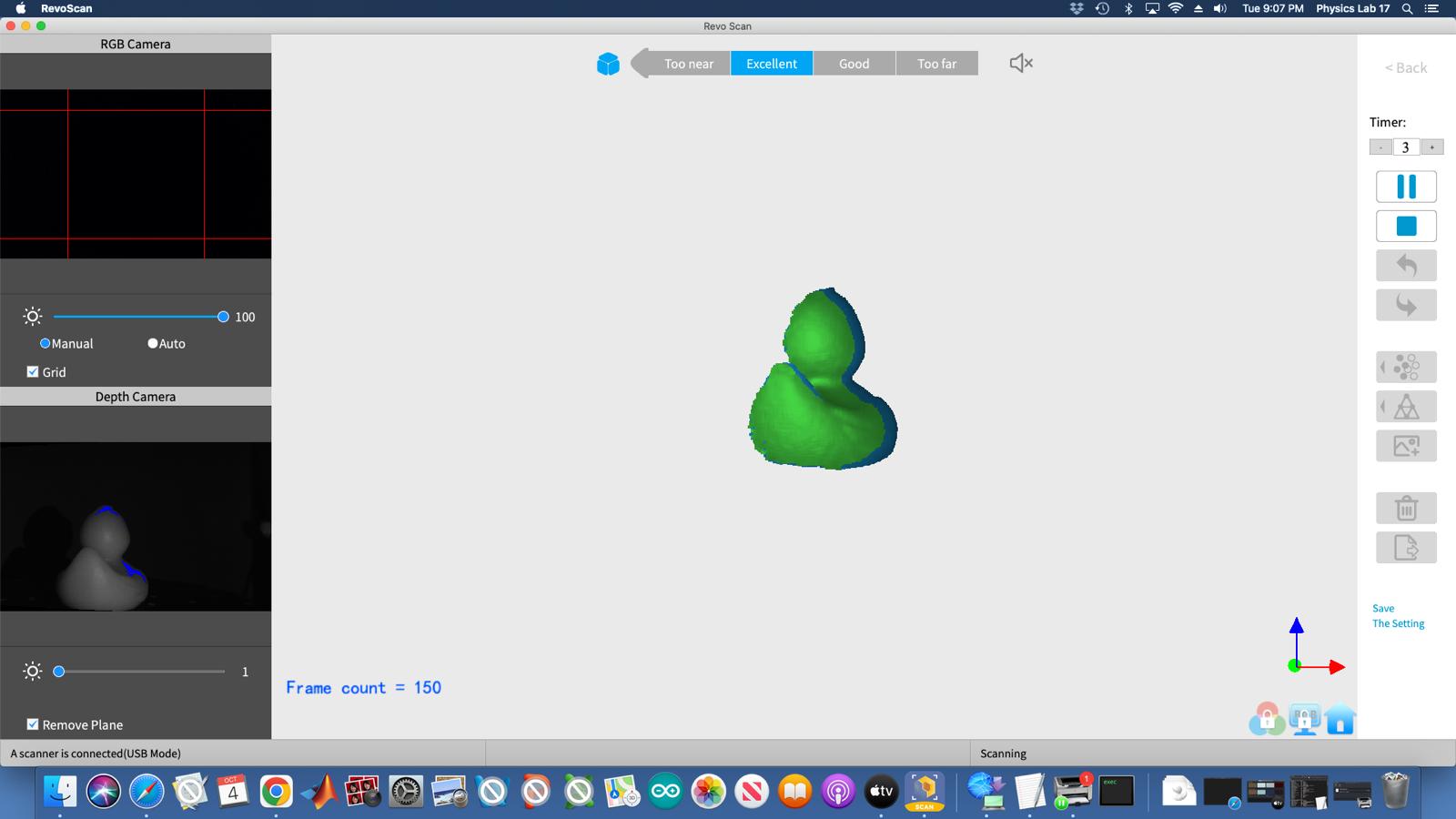

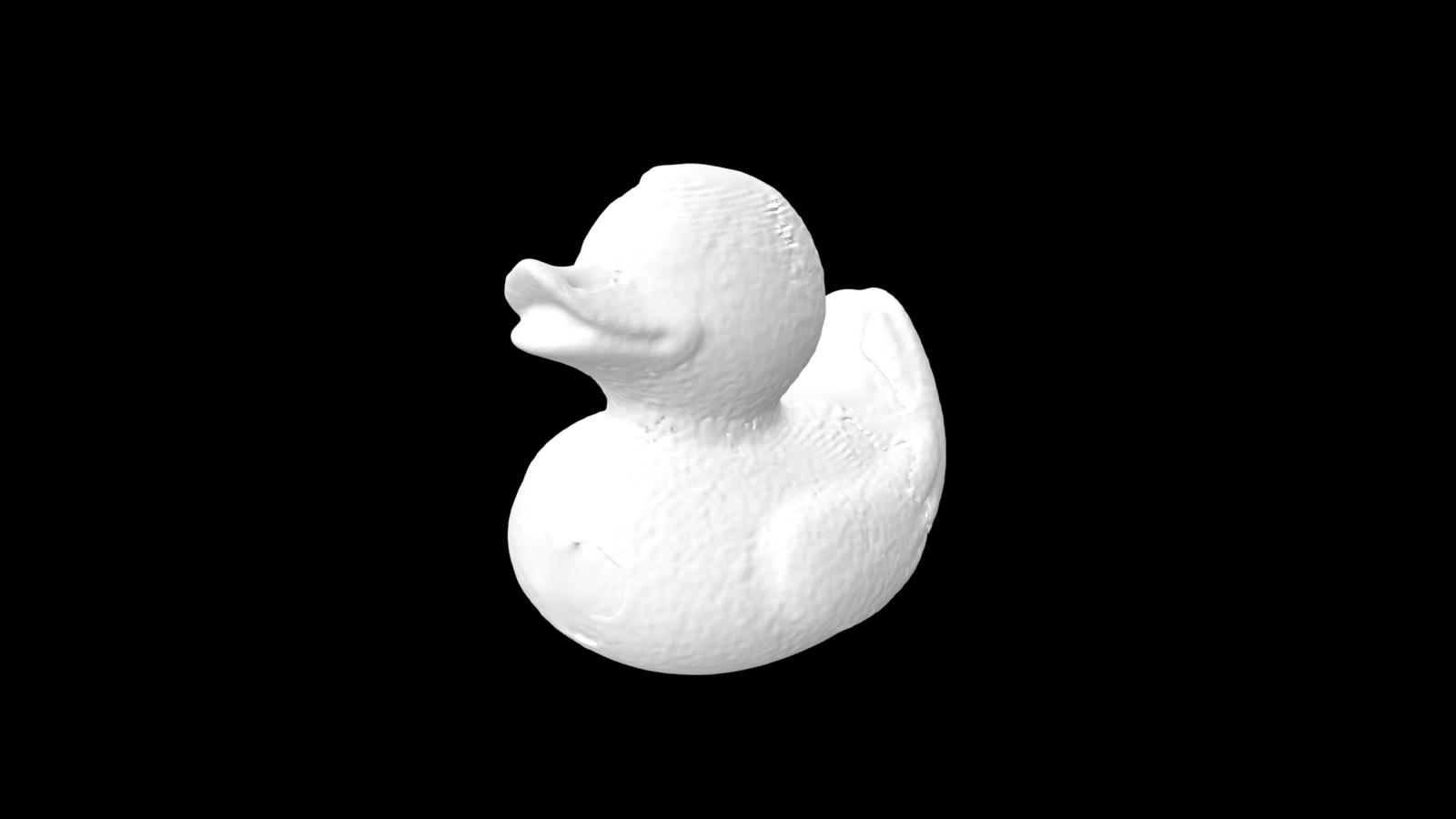

2. 3D Scanning

This in theory was really cool. But my excitement was squashed as I began running into errors in the program. I immediatley thought about putting a cool ring on the spinner. But since it was shiny it did not pick up anything. I put on a cool pair of classes but in the end that failed as well. Then I put a rubber duck on it and that start off well although as I was trying to get different angles the program could not seem to get the duck well. What the Duck. Am I Right? In the end I needed to wait for it to go around many times before getting a good stl file.